About MicroMaterials

Welcome to MicroMaterials LLC, where innovation meets precision in the world of micro

and nano particle technology!

At MicroMaterials, we are pioneers in developing cutting-edge technologies for the synthesis and processing of micro and nano particles. Our tailored particles, with their unique shapes and structures, are designed for high-precision grinding and polishing, as well as for hosting and delivering various chemical species. These versatile particles have a wide range of applications, including:

-

Energy storage solutions

-

Advanced drug delivery systems

-

Processing bioimplants

-

Manufacturing mechanics, optics, and semiconductors

Our current R&D projects are pushing the boundaries of science and technology:

-

Synthesis of Ultrapure, Monodispersed Spherical Nano Silica Particles: Achieving new levels of purity and consistency in nano silica production.

-

Fabrication of <10 Multiphase Micron Microspheres: Creating complex microspheres with unparalleled precision and versatility.

-

Innovative Equipment Development: Breaking through existing limitations to create advanced synthesis and fabrication tools for specially demanded micro/nano particles

Join us at MicroMaterials LLC, where we are shaping the future, one step at a time.

Innovations

Innovation on Stöber method

The Stöber method is widely used by chemists to synthesize high-purity, monodispersed nano silica particles. Traditionally, this method requires a large amount of ethanol as the synthesis

medium. Despite its recyclability, ethanol poses significant safety and health risks due to its flammability and toxicity.

We have revolutionized the Stöber process by eliminating the use of ethanol and other alcohols, utilizing pure water instead. With advancements in producing ultrahigh purity (UHP) water and purifying TEOS, our innovation shows great promise for the application in UHP nano silica production.

Concept of Chemical Domains

Functional and structural materials often consist of multi-component mixtures. Traditional manufacturing involves top-down processes to co-mill raw materials, achieving high mix homogeneity. While effective for larger particles, this approach faces challenges in preventing segregation when producing ultrafine microparticles.

Drawing inspiration from magnetic and electric domains in ferromagnetic and ferroelectric materials, we introduced the concept of chemical domains. A chemical domain is the smallest volume unit in a mixture that meets the stoichiometry of the designated formula.

By characterizing the homogeneity of mixed materials through chemical domains, we aim to develop techniques to control these domains. Our approach enables us to produce spherical particles less than 10 microns in a top-down process without segregation issues.

Radially Channel-Shaped Porous Particles

Radial channel porous spherical microparticles hold great potential for chemical catalysis and energy storage applications. In batteries, incorporating channel-shaped voids in positive electrodes, negative electrodes, or separators can transform ion motion from bulk diffusion to surface diffusion. This significantly reduces ionic transport resistance, lowers battery internal resistance, enhances effective output power, minimizes polarization, and prevents the formation of needle-like deposits at the electrode-separator interface, thereby improving battery stability and safety.

While porous particles are common, spherical particles with radially channel-shaped pores are rare. Our innovation has successfully produced macro-sized spherical particles with well- distributed radially channel-shaped pores. We are currently researching methods to reduce particle size to the microscale.

Products

Product: Polishing Pad NPU15

Use/Application:

precision grinding of silicon carbide wafers

Features:

-

Hardness: 90-92 A

-

Density: 630 ± 30 kg/m^3

-

Cutting rate: 0.377-0.469 µm/minute

Product: Polishing Pad-NPU66

Description:

mat made of double system polyurethane resin, using cerium oxide as the filler. Available in different hardnesses, can be backed with adhesives and slots per customer’s requirements.

Use/Application:

precision grinding of optical wafers

Features:

-

High cutting rate with minimal scratches

-

Ability to produce more stable aperture of processed product

-

Long service life

-

High corrosion resistance

-

Hardness: 77 ± 4 A

-

Density: 420 ± 50 kg/m^3

-

Filler: Cerium oxide

-

Cutting rate: 0.48 µm/minute

Product: Polishing Pad-NPU57

Use/Application:

polishing glass

Features:

-

Resistance to acid and alkali, other corrosive substances

-

Excellent wear resistance

-

High cutting rate

-

Hardness: 90 ± 2 A

-

Density: 630-650 kg/m^3

-

Tensile strength: 1.27 MPa

-

Elongation at breaking: 55%

Product: Polishing Pad-NPU80

Description:

different from traditional non-woven series. Adopts the process of composite of filler and polyurethane resin.

Use/Application:

coarse polishing of silicon carbide wafers

Features:

-

Hardness: 88-90 4 A

-

Density: 630 ± 30 kg/m^3

-

Cutting rate: 0.808-0.871 µm/hour

Product: Ordinary Colloidal Silica Products

Description:

pH and particle size can be customized according to customer needs.

Use/Application:

preparing polishing slurry, rough polishing of wafers, ceramics, metals, glass, other materials; special coatings

Features:

-

Narrow particle size distribution

-

High particular density

-

Fast polishing rate

Product: High-Purity Colloidal Silica Products

Description:

silica particles are silkworm-like in shape, which improves the polishing rate and surface quality. The metal ion can be stably controlled.

Use/Application:

formulation of polishing slurry for precision polishing of wafers and integrated circuits.

Features:

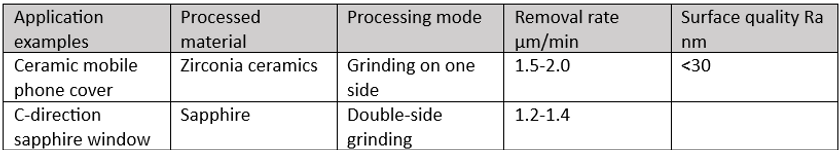

Product: Aggregate Diamond Micropowder

-

Test equipment: 13B double-sided grinder

-

Grinding pad model: Resin abrasive pad NP-100

-

Grinding pad size: 910x270 m

-

Grinding disk speed: lower wall: 35 rpm

-

Material size and quantity: sapphire C-directional piece 42 x 1.0 mm x 44 pcs

-

Abrasive flow rate: 14.8 mL/minute

-

Working pressure: 290 g/cm^2

-

Grinding time: 30 minutes

Product: Agglomerated Diamond Grinding Fluid (DL0208)

Description:

slurry formulated with 8µm diamond aggregates as its abrasives. Prepared by using 0.2µm of single crystalline diamond to agglomerate into 8µm particles

Use/Application:

CMP process; produce high quality surface with fewer scratches

Product: Agglomerated Diamond Grinding Fluid (DL1522)

Description:

slurry formulated with 22µm diamond aggregates as its abrasives. Prepared by using 1.5µm of single crystalline diamond to agglomerate into 22µm particles

Use/Application:

polishing of ceramics; produce high quality surface with fewer scratches

Product: Agglomerated Diamond Grinding Fluid (DL1532)

Description:

slurry formulated with 32µm diamond aggregates as its abrasives. Prepared by using 1.5µm of single crystalline diamond to agglomerate into 22µm particles

Use/Application:

excellent removal rate and surface quality

Product: Agglomerated Diamond Grinding Fluid (DL1548)

Description:

slurry formulated with 48µm diamond aggregates as its abrasives. Prepared by using 1.5µm of single crystalline diamond to agglomerate into 48µm particles

Use/Application:

fast cutting rate

Product: Agglomerated Diamond Grinding Fluid (DL3035, DL4045)

Description:

slurry formulated with 35µm diamond aggregates as its abrasives. Prepared by using 3.0µm of single crystalline diamond to agglomerate into 35µm particles

Use/Application:

fast cutting rate

Product: Diamond Reduced Grinding Wheel

Description:

excellent performance, designed according to the material characteristics of silicon carbide, divided into two kinds of diamond grain size grinding wheels: 2000# coarse grinding & thinning, and 8000-30000# fine grinding & thinning, which can match different grinding wheel sizes according to customer equipment

Use/Application:

grinding materials

Features:

-

Self-sharpness (maintain grinding wheel sharpness, high cutting ability)

-

High form retention (long service life)

-

High chip capacity for chip evacuation

-

Easy-to-repair type (low-speed repairable type)

-

Low scratch rate, low fragmentation rate

-

High cutting rate with minimal scratches

Capabilities

Synthesis of UHP nanoparticles and colloids

-

Clean glove box is the key equipment

-

Laboratory scale synthesis can be carried out inside the box

-

Combination of equipment inside the glove box and outside the glove box enables our synthesis in pilot scales

making ultrafine microparticles

-

Upgraded spray dryer is the major equipment capable of producing 5kg green particles per hour.

-

Nano grinder, capable of grinding down coarse particles into below 100 nano powders, is the key equipment for making sub-10 micron multi-component aggregate with homogenous microstructures.

-

Furnaces are capable of heating up to 1800°C in vacuum and ambient atmosphere as well as under controlled gaseous atmospheres, making the lab versatile for high temperature processing of nanoparticles with various chemical compositions.

-

Particle size classifier is able to separate particles into a series of particles of narrow size ranges, making the lab capable of making neo-mono dispersed micro/nano particles

Analysis and characterization

-

A brand new Nexion 2000 ICP-MS was stalled in March 2024, capable of analyzing trace metal ions in UHP nano materials

-

A brand new Anton Paar LITESIZER 500 was installed in August 2022, capable of analyzing particle size ranging from 0.3 nm to 10 μm

-

pH, electrical conductivity & solid content analyzer are employed to in situ monitor the synthesis process

-

Optical microscope is employed to examine the size and shape of particles in micron range

-

Polishing tester is employed to test the abrasive performance of micro & nano particles

Equipment Innovation Lab

-

Equipment innovation for technological breakthroughs on micro/nano particles synthesis and processing is one of our ambitions

-

Desktop 3D printer, CNC router, drill and mini lathe are employed to make testing parts of new equipment prototypes

-

An 1300*1500*200mm CNC router and an 1 hp 7.5x12” band saw are installed for development of industrial scale equipment

-

Bread board muddle, signal generator, oscilloscope, microscope and multi-electrical measurement instruments are employed to design and test electrical, electronics hardware and software

AI Implementation

AI Implementation

The advent of AI is bringing both excitement and concern to the scientific community and society as a whole. AI can undoubtedly accelerate the development of science and technology at an unprecedented pace, but it also has the potential to cause catastrophic disasters if not properly managed. At Micro Materials, we take a positive view of AI’s impact. We have been integrating AI into our R&D activities, exploring its functions and potential benefits. Below are a few case studies that represent our efforts and the advantages AI can bring:

• Understanding Class 100 Clean Rooms:

We determined that a Class 100 clean room is essential for synthesizing UHP nanoparticles. Understanding the requirements of a clean room is necessary to obtain satisfactory equipment. For researchers specialized in chemistry, materials science, and engineering, it is common to lack knowledge regarding clean rooms. To expand our knowledge efficiently, we turned to AI for assistance. The AI provided us with the necessary information for creating a Class 100 clean room, including the selection of appropriate materials and HEPA filters, the design of airflow systems, and the implementation of protocols to maintain cleanliness and control contamination.

• Training Employees on Using Autodesk Fusion 360:

We hired an intern for our equipment innovation program, who needed to use Autodesk Fusion 360 for prototype design but was unfamiliar with the software. Training new employees with a human tutor consumes the time of our senior staff, and YouTube videos often do not meet specific needs within a tight timeframe. To address this, we utilized AI for training. By providing the AI with details of the specific model to be built, the intern received tailored instructions on using the relevant tools in the Fusion 360 workspace, following a step-by-step procedure in just a few minutes. This approach enabled concurrent learning and working, demonstrating the potential to transform traditional employee training programs into more efficient and customized learning courses.

• Tracking the Course of Sodium Contamination by AI-assisted ICP-MS Analysis:

ICP-MS is a powerful analytical tool for the research and development of UHP nanomaterials. We installed an ICP-MS instrument in early 2024. After a few runs of analysis, we detected unexpected sodium contamination. To address this, both our human expert and AI were tasked with tracking the source of the sodium contamination. While the human expert took several days to determine the cause, the AI provided similar answers in minutes! Although the current expertise level of AI cannot yet match that of our human expert, it has significantly reduced our effort and allowed our human experts to focus on more in-depth research issues.

• AI-assisted Design of Experiment (AI-DOE):

Many R&D and manufacturing firms commonly use Design of Experiments (DOE) to plan, conduct, and analyze experiments using statistical methods to understand the influence of various factors and improve the efficiency and performance of their products. However, commercial DOE software is often sophisticated and time-consuming to learn. Implementing AI in DOE is one of our new ventures. Currently, we use AI to generate factorial experiment tables, which are identical to those produced by commercial software. We continue to leverage AI to explore more functions within the commercial DOE software and develop expertise in utilizing these functions.

• Editing G-code to Change 3D Printer Functions:

We are using 3D printers to make prototype equipment parts but found that they can also serve as XYZ motion platforms for other purposes. Editing the G-code is an effective approach to modify the functions of a 3D printer. We utilize AI to assist us with G-code editing to improve our work efficiency. AI provides us with general G-code examples for 3D printing and CNC routing and explains unfamiliar commands, from which we develop our own programs for specific purposes. Additionally, AI helps us debug programs and troubleshoot issues. The assistance of AI enables less experienced professionals to perform tasks typically reserved for experts and shows promise for revolutionizing professional education.

• Analytical Study of the Business Specialties of Exhibitors Participating in a Conference:

We are preparing to attend a conference in the summer of 2024. Conducting an analytical studyon the business specialties of the exhibitors at the conference will facilitate our interactions with them. With over 600 exhibitors, this task appears daunting. However, by implementing AI, we can complete the study in just one day. With only a few instructions, AI can extract keywords related to the exhibitors' business specialties and compile them into an Excel worksheet, along with the exhibitor's name, booth number, website address, physical address, and contact phone number. AI can further sort and regroup the exhibitors in the worksheet based on various categories.

Services

• Short-term Facility Rental:

Our lab is fully equipped for experimenting with the synthesis of UHP materials. Renting our facility to conduct your own experiments will save you time, reduce costs, and accelerate your R&D progress.

• Contracted R&D and Technology Transfer:

Having new materials and the corresponding processing technologies is key to business success. For many small businesses, however, building an R&D team and operating an R&D lab are costly. We specialize in the synthesis and processing of micro/nano particles. If you are pursuing technology in this area, our service is your best choice.

• Preparation of On-demand R&D Samples:

Many R&D teams outsource precursors and intermediates to accelerate their innovations in micro/nano particle applications. Our expertise and lab facilities can satisfy your needs.

• Toll Spray and Pilot Scale Production Trials:

Looking to validate your lab outcomes on a pilot scale or scale up your process from lab preparation to commercial production? Use our facilities, which include 30-100 liter reflux, hydrothermal, and evaporation reactors for synthesizing nanoparticles in kilogram scales, or our 7.6' x 13' spray dryer for producing ultrafine microparticles at a rate of 5 kg per hour.